Epdm resists abrasion and weather.

Double fire door gaps.

The development of fire door testing.

Gaps between fire doors and the door frame should never be more than 4mm or less than 2mm.

It s recommended to aim for a 3mm gap to ensure adequate room for the intumescent strips to activate in the event of a fire and for the smoke seal strips if installed to not get damaged by the opening and closing of the door.

Nfpa 80 fire doors and other opening protectives.

Vinyl is the most economical choice.

Flat seals press against surfaces to create a seal.

1 8 meeting edges for a pair of doors.

The filaments are nylon for good wear resistance.

Best practice guidance states that the gaps at the sides and top of a timber fire door should be between 2 and 4mm.

Worryingly the fire door inspection scheme.

You can measure the gap with a simple gap gauge.

They are abrasion resistant neoprene.

3 4 between door and frame.

How big should gaps around fire doors be.

The smoke and the fire will try to push through the side and top gaps around a fire door while usually drawing air from underneath the door.

The old test of fire doors to bs 476 part 8 for fire resistance was carried out simply in a furnace increasing the temperature to that found in rooms on fire and.

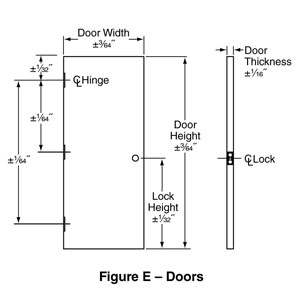

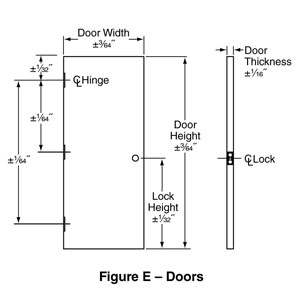

In general clearance for those allowed gaps are as follows.

Brush seals have flexible filaments that conform to fill gaps.

Which is designed to expand when temperatures reach beyond 200 c to seal the gaps between the door and frame.

1 8 for more detailed gap information refer to nfpa 80 section 6 3 1 7 and section.

Wraparound seals create a seal on both sides of a door.

Under the bottom of a door.

Contains information on maximum gap allowances for different types of fire doors.

Seal the space between your double doors.